We use cookies to ensure you get the best experience on our website. This includes personalisation of content and ads, to provide social media features and to analyse our traffic. We also share information about your use of our site with our social media, advertising and analytics partners who may combine it with other information that you’ve provided to them or that they’ve collected from your use of their services.

- Necessary cookies help make a website usable by enabling basic functions like page navigation and access to secure areas of the website. The website cannot function properly without these cookies.

- 683ecd8adc82.1051d031.eu-central-1.token.awswaf.com5awswaf_session_storageEnsures visitor browsing-security by preventing cross-site request forgery. This cookie is essential for the security of the website and visitor.awswaf_token_refresh_timestampThis cookie is used to distinguish between humans and bots.aws-waf-token [x3]Used to encrypt and contain visitor data. This is necessary for the security of the user data.

- Cookiebot2Learn more about this providerCookieConsent [x2]Stores the user's cookie consent state for the current domain

- Google1Learn more about this provider

Some of the data collected by this provider is for the purposes of personalization and measuring advertising effectiveness.

test_cookiePending - HubSpot2Learn more about this provider_cfuvid [x2]This cookie is a part of the services provided by Cloudflare - Including load-balancing, deliverance of website content and serving DNS connection for website operators.

- LinkedIn2Learn more about this providerbcookiePendingli_gcPending

- YouTube2Learn more about this providerVISITOR_INFO1_LIVEPendingyt-remote-session-nameStores the user's video player preferences using embedded YouTube video

- cdn.jsdelivr.net1_ALGOLIANecessary in order to optimize the website's search-bar function. The cookie ensures accurate and fast search results.

- feefo.com

hubapi.com3__cf_bm [x3]This cookie is used to distinguish between humans and bots. This is beneficial for the website, in order to make valid reports on the use of their website. - nr-data.net

www.tradeprint.co.uk2JSESSIONID [x2]Preserves users states across page requests. - ready-set-print.tradeprint.co.uk1SESS#Preserves users states across page requests.

- www.tradeprint.co.uk14anonymousIdPendingAWSALBRegisters which server-cluster is serving the visitor. This is used in context with load balancing, in order to optimize user experience.AWSALBCORSRegisters which server-cluster is serving the visitor. This is used in context with load balancing, in order to optimize user experience.AWSALBTGRegisters which server-cluster is serving the visitor. This is used in context with load balancing, in order to optimize user experience.AWSALBTGCORSRegisters which server-cluster is serving the visitor. This is used in context with load balancing, in order to optimize user experience.cookies-acceptedThe purpose is to track whether the user has accepted the site's cookie policy or declaration.gamificationPopupgamificationPopuporderCountThe purpose is to keep a counter for the number of orders a user has placed.pricing-grid-viewThe primary purpose is to remember the user's preferred way of viewing product pricing.rc::d-15#This cookie is used to distinguish between humans and bots.TIDPreserves the visitor's session state across page requests.tp-customer-tierThe purpose is to identify the tier level of logged-in users.VATPrefrencePendingwdThis cookie stores the browser window dimensions and is used by Facebook to optimise the rendering of the page.

- 683ecd8adc82.1051d031.eu-central-1.token.awswaf.com

- Preference cookies enable a website to remember information that changes the way the website behaves or looks, like your preferred language or the region that you are in.

- HubSpot1Learn more about this providermessagesUtkStores a unique ID string for each chat-box session. This allows the website-support to see previous issues and reconnect with the previous supporter.

- LinkedIn1Learn more about this providerlidcPending

- HubSpot

- Statistic cookies help website owners to understand how visitors interact with websites by collecting and reporting information anonymously.

- Google8Learn more about this provider

Some of the data collected by this provider is for the purposes of personalization and measuring advertising effectiveness.

_ga [x2]Used to send data to Google Analytics about the visitor's device and behavior. Tracks the visitor across devices and marketing channels._ga_# [x2]Used to send data to Google Analytics about the visitor's device and behavior. Tracks the visitor across devices and marketing channels._gat [x2]Used to send data to Google Analytics about the visitor's device and behavior. Tracks the visitor across devices and marketing channels._gid [x2]Registers a unique ID that is used to generate statistical data on how the visitor uses the website. - HubSpot8Learn more about this provider__hssc [x2]Identifies if the cookie data needs to be updated in the visitor's browser.__hssrc [x2]Used to recognise the visitor's browser upon reentry on the website.__hstc [x2]Sets a unique ID for the session. This allows the website to obtain data on visitor behaviour for statistical purposes.hubspotutk [x2]Sets a unique ID for the session. This allows the website to obtain data on visitor behaviour for statistical purposes.

- Microsoft5Learn more about this provider_clck [x2]Collects data on the user’s navigation and behavior on the website. This is used to compile statistical reports and heatmaps for the website owner._clsk [x2]Registers statistical data on users' behaviour on the website. Used for internal analytics by the website operator._cltkRegisters statistical data on users' behaviour on the website. Used for internal analytics by the website operator.

- Segment3Learn more about this providerajs_anonymous_idThis cookie is used to count how many times a website has been visited by different visitors - this is done by assigning the visitor an ID, so the visitor does not get registered twice.ajs_anonymous_idThis cookie is used to identify a specific visitor - this information is used to identify the number of specific visitors on a website.ajs_user_idThis cookie is used to collect data on the visitor's behavior on the website - this information can be used to assign the visitor to a visitor segment, based on common preferences.

- www.tradeprint.co.uk1mf_userThis cookie establishes whether the user is a returning or first-time visitor.

- Google

- Marketing cookies are used to track visitors across websites. The intention is to display ads that are relevant and engaging for the individual user and thereby more valuable for publishers and third party advertisers.

- Meta Platforms, Inc.5Learn more about this provider_fbp [x2]Used by Facebook to deliver a series of advertisement products such as real time bidding from third party advertisers.lastExternalReferrerDetects how the user reached the website by registering their last URL-address.lastExternalReferrerTimeDetects how the user reached the website by registering their last URL-address.log/errorUsed to detect and log potential tracking errors.

- Feefo1Learn more about this providerfeefoUserIdUsed in context with SEO and conversion optimization. Gathers any user reports or behavioral data into reports for the website operator. This service is provided by a third-party analysis-service.

- Google5Learn more about this provider

Some of the data collected by this provider is for the purposes of personalization and measuring advertising effectiveness.

_gcl_au [x2]Used to measure the efficiency of the website’s advertisement efforts, by collecting data on the conversion rate of the website’s ads across multiple websites.IDEUsed by Google DoubleClick to register and report the website user's actions after viewing or clicking one of the advertiser's ads with the purpose of measuring the efficacy of an ad and to present targeted ads to the user.pagead/1p-user-list/#Tracks if the user has shown interest in specific products or events across multiple websites and detects how the user navigates between sites. This is used for measurement of advertisement efforts and facilitates payment of referral-fees between websites._gcl_lsTracks the conversion rate between the user and the advertisement banners on the website - This serves to optimise the relevance of the advertisements on the website. - HubSpot5Learn more about this provider__ptbe.gifPending__ptq.gifSends data to the marketing platform Hubspot about the visitor's device and behaviour. Tracks the visitor across devices and marketing channels.outpost/video-embed/error.gifPending__hmplCollects information on user preferences and/or interaction with web-campaign content - This is used on CRM-campaign-platform used by website owners for promoting events or products.HUBLYTICS_EVENTS_53Collects data on visitor behaviour from multiple websites, in order to present more relevant advertisement - This also allows the website to limit the number of times that they are shown the same advertisement.

- Microsoft9Learn more about this provider_uetsidUsed to track visitors on multiple websites, in order to present relevant advertisement based on the visitor's preferences._uetsid_expContains the expiry-date for the cookie with corresponding name._uetvidUsed to track visitors on multiple websites, in order to present relevant advertisement based on the visitor's preferences._uetvid_expContains the expiry-date for the cookie with corresponding name.MUIDPending_uetsid [x2]Collects data on visitor behaviour from multiple websites, in order to present more relevant advertisement - This also allows the website to limit the number of times that they are shown the same advertisement._uetvid [x2]Used to track visitors on multiple websites, in order to present relevant advertisement based on the visitor's preferences.

- Segment3Learn more about this providerajs_user_idCollects data on visitors' preferences and behaviour on the website - This information is used make content and advertisement more relevant to the specific visitor.__tld__ [x2]Used to track visitors on multiple websites, in order to present relevant advertisement based on the visitor's preferences.

- YouTube17Learn more about this provider__Secure-ROLLOUT_TOKENUsed to track user’s interaction with embedded content.__Secure-YECStores the user's video player preferences using embedded YouTube video__Secure-YNIDPendingLAST_RESULT_ENTRY_KEYUsed to track user’s interaction with embedded content.LogsDatabaseV2:V#||LogsRequestsStoreUsed to track user’s interaction with embedded content.remote_sidNecessary for the implementation and functionality of YouTube video-content on the website.TESTCOOKIESENABLEDUsed to track user’s interaction with embedded content.YSCPendingyt-icons-last-purgedPendingytidb::LAST_RESULT_ENTRY_KEYUsed to track user’s interaction with embedded content.YtIdbMeta#databasesUsed to track user’s interaction with embedded content.yt-remote-cast-availableStores the user's video player preferences using embedded YouTube videoyt-remote-cast-installedStores the user's video player preferences using embedded YouTube videoyt-remote-connected-devicesStores the user's video player preferences using embedded YouTube videoyt-remote-device-idStores the user's video player preferences using embedded YouTube videoyt-remote-fast-check-periodStores the user's video player preferences using embedded YouTube videoyt-remote-session-appStores the user's video player preferences using embedded YouTube video

- lantern.roeye.com1track.phpCollects data on the user across websites - This data is used to make advertisement more relevant.

- www.tradeprint.co.uk4datrThe purpose of the datr cookie is to identify the web browser being used to connect to Facebook independent of the logged in user.mf_#Collects data of the user's navigation and interaction on the website in order to personalise the purchasing experience.SourceThe primary purpose is to track the source from which the user was redirected, particularly for facilitating the payment of commissions for affiliate marketing via AWIN.Welcome10OfferThe primary purpose is to track whether a welcome pop-up advertising a discount code should be shown to the user.

- Meta Platforms, Inc.

- Unclassified cookies are cookies that we are in the process of classifying, together with the providers of individual cookies.

- 683ecd8adc82.1051d031.eu-central-1.token.awswaf.com1aws_waf_referrerPending

- lantern.roeyecdn.com1lanternPending

- ready-set-print.tradeprint.co.uk

www.tradeprint.co.uk2hs-cta-interactions#cta [x2]Pending - roeye.com1#_lanternPending

- www.tradeprint.co.uk3ABC_SESSIONunclassifiedoptimizely_session_idPendingoptimizely-vuidPending

- 683ecd8adc82.1051d031.eu-central-1.token.awswaf.com

The law states that we can store cookies on your device if they are strictly necessary for the operation of this site. For all other types of cookies we need your permission.

This site uses different types of cookies. Some cookies are placed by third party services that appear on our pages.

You can at any time change or withdraw your consent from the Cookie Declaration on our website.

Learn more about who we are, how you can contact us and how we process personal data in our Privacy Policy.

Please state your consent ID and date when you contact us regarding your consent.

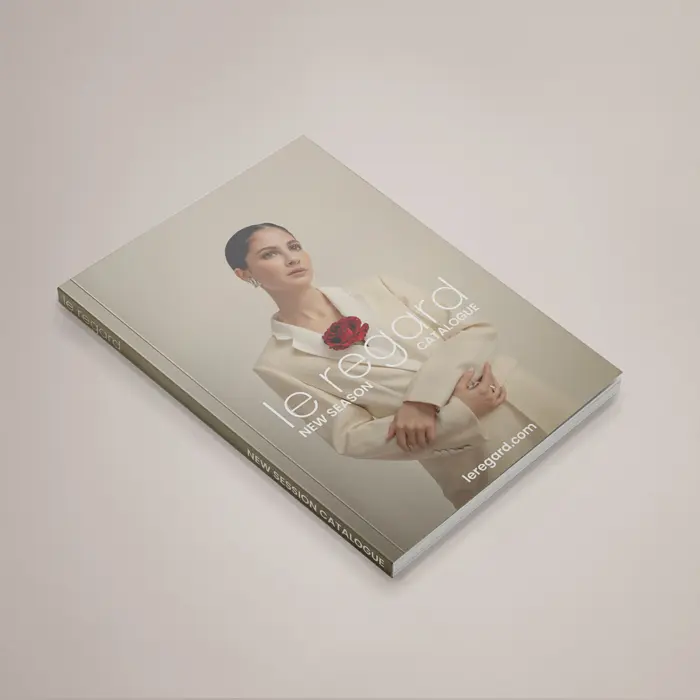

Recommended products

Saddle Stitch Booklets

Classic Flyers

Online Designer

Classic Curve Coloured Grip Pen

Classic Business Cards